Suitable For:

- Civic Mk8 Hatchback FK1 1.4 / FK1, FN4 1.4

- Civic Mk8 FK3 2.2 CDTi

- Civic Mk8 FN1, FK2 1.8

- Civic Mk8 FN2 2.0 Type R

The range of HEL Performance brake pads has been tested and proven in a range of competitive MSA championships and racing series in the United Kingdom and Europe

With an impressive operating temperature window of 0-800°C, these pads will handle the most serious braking conditions and are developed exclusively for racing or track day use

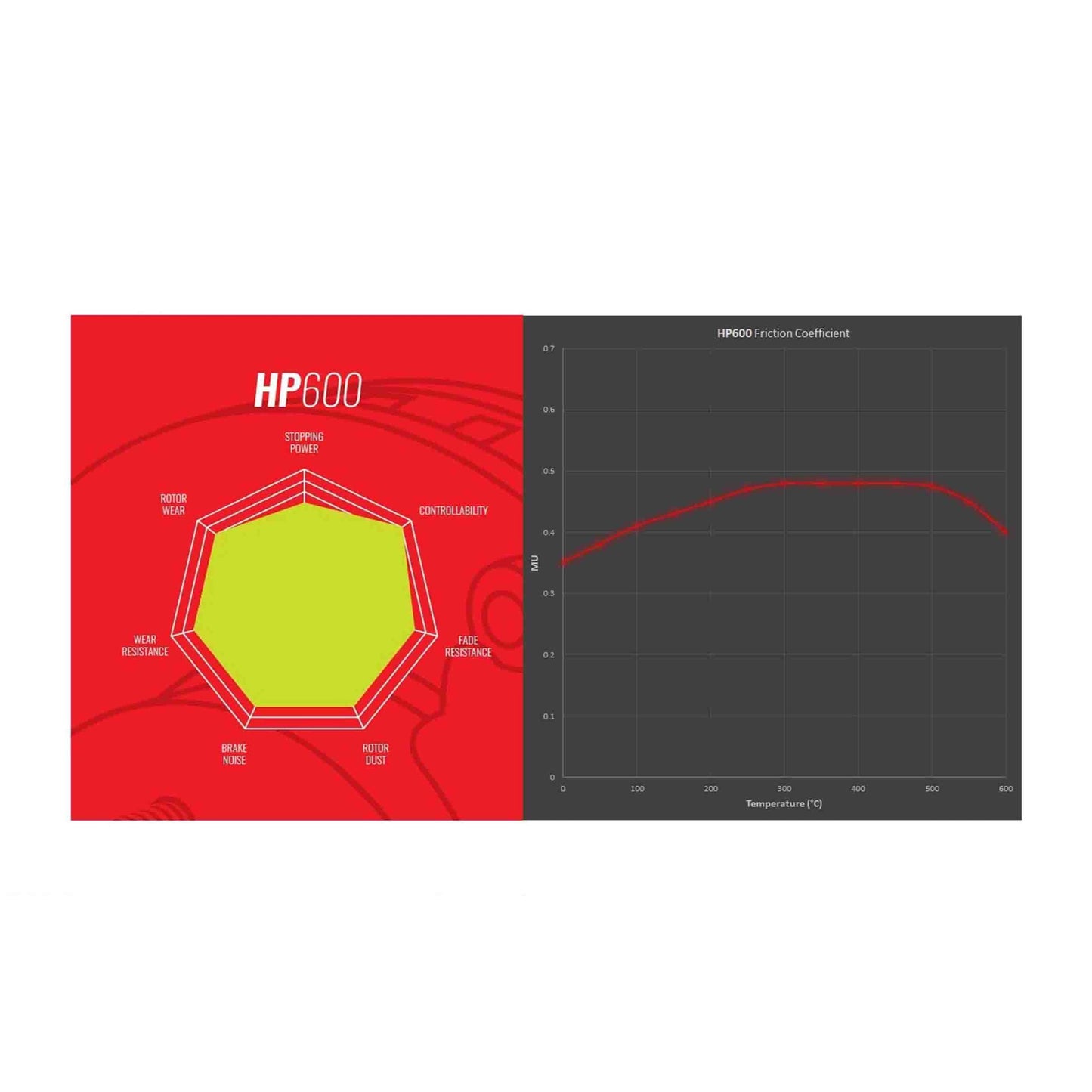

HP600

The HP600 also has a ceramic super metal compound that has a milder initial bite than the HP666 but still retains the same excellent control and pedal feel with a powerful friction coefficient of 0.35–0.48μ over a temperature range of 0-600°C. This is a great all-around track day pad that will outperform a lot of more expensive pads. Similar in the compound to the Ferodo DS2500, we have had very good results combining this pad with a plain disc such as Pagid

Eliminating Brake Fade

When brake pads run at high temperatures, a layer of gas can sometimes be created between the pad and the brake disc. This can make the driver feel like they have lost braking power as the brake pedal feels the same but the car will not stop as quickly, this is called brake fade. To remedy this, a slot is cut into all HEL Performance pads to offer the gasses a route to escape

NUCAP NRS Hooked Back Plate

Because brake pads are subjected to huge pressures from the pistons, the back plate of the pad must remain flat to offer optimal performance. We use NUCAP NRS hooked back plates so there is both a mechanical and adhesive bond between the pad friction material and the back plate

The "Bulletproof" NRS system has hundreds of steel hooks that create a permanent bond with the friction material. This mechanical attachment holds the friction material better than any adhesive could

NRS also allows the pad to be run down to the last few millimetres of friction material, while still maintaining 100% retention, increasing the lifespan of your brake pads and saving you money on replacements

Bedding In

HEL Performance brake pads are put through a heat curing treatment in the manufacturing process. This process removes unwanted gasses from the materials in advance, reducing the gasses that can cause fade within the brake pad. Because of this treatment, our brake pads only need light bedding in to match the padding to the disc

Brake pads should be bedded in until up to mid-range working temperature and then allowed to cool properly. This will also help to remove any gasses that are still within the pad. Not following this process may cause problems leading to a decrease in optimum performance

Designed and manufactured in the UK